| CALL US TODAY! | Mississauga (905) 625-4664 |

5170 Dixie Rd Mississauga, ON L4W 1E3 |

• | Scarborough (416) 299-4960 |

48 Continental Place Scarborough, ON M1R 2T4 |

SITE MAP |

Poly-Caster

De-Icing Technology. Evolved.

Winter storms hit fast and hard. Fight back with the FISHER® POLY-CASTER™ hopper spreader, loaded with upgraded de-icing technology to get you in and out of the storm quickly. Enhanced controls, a convenient accessory hub and the FLEET FLEX interchangeable electrical system give you the tools you need to make the best use of your de-icing materials. Conquer every storm with the easy-to-install POLY-CASTER hopper spreader.

TYPE OF SPREADERS

Truck Bed

|

|

|

|

Contact a Hitch City near you to find out how to outfit your FISHER® POLY-CASTER™ Poly Hopper Spreader

|

|

|||

Cover |

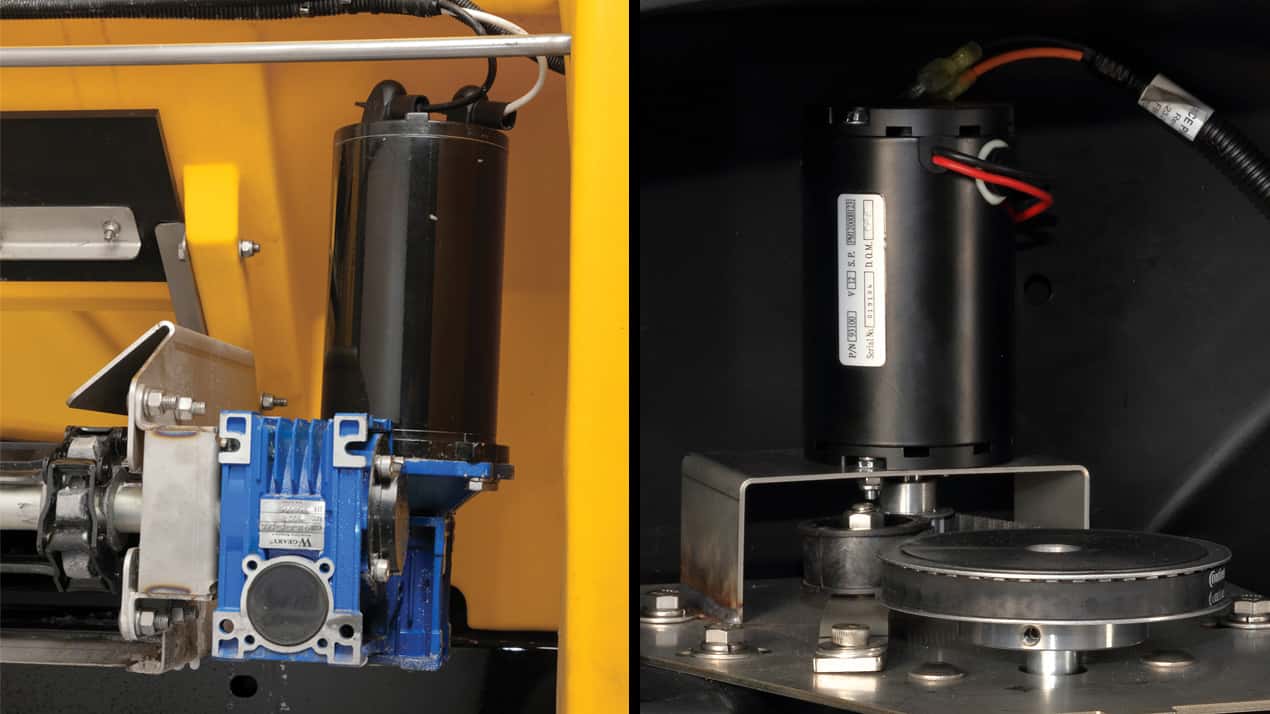

Dual Electric Motors |

|||

| The overlapping poly hopper covers shield de-icing material from the elements. Its design seals out moisture, while molded grooves direct water away from the hopper, and its domed shape increases hopper capacity.

In the open position, the covers act as spill guards and protect the truck from material overflow while loading. |

The two high-torque 12-volt electric motors provide quiet, reliable and independent control over the conveyor and spinner mechanisms. The spinner motor is sealed inside a weather-resistant housing, protecting it from corrosion. | |||

|

|

|||

Controls |

Corrosion-Resistant Hopper |

|||

| Enhanced dual variable-speed control allows you to precisely match material delivery and spread patterns to conditions. Four standard accessory buttons and a dedicated blast button provide optimum in-cab efficiency.

Easy-to-understand, digital self-diagnostics alert the operator when the spreader is empty or when adjustments are needed, and LEDs make the control easy to read. Its compact size compared to traditional controls fits easily into today’s modern truck cab designs. |

The proven double-walled hopper is built of durable poly for corrosion-free performance, whether using rock salt, calcium chloride, sand or any other type of de-icing material. | |||

|

|

|||

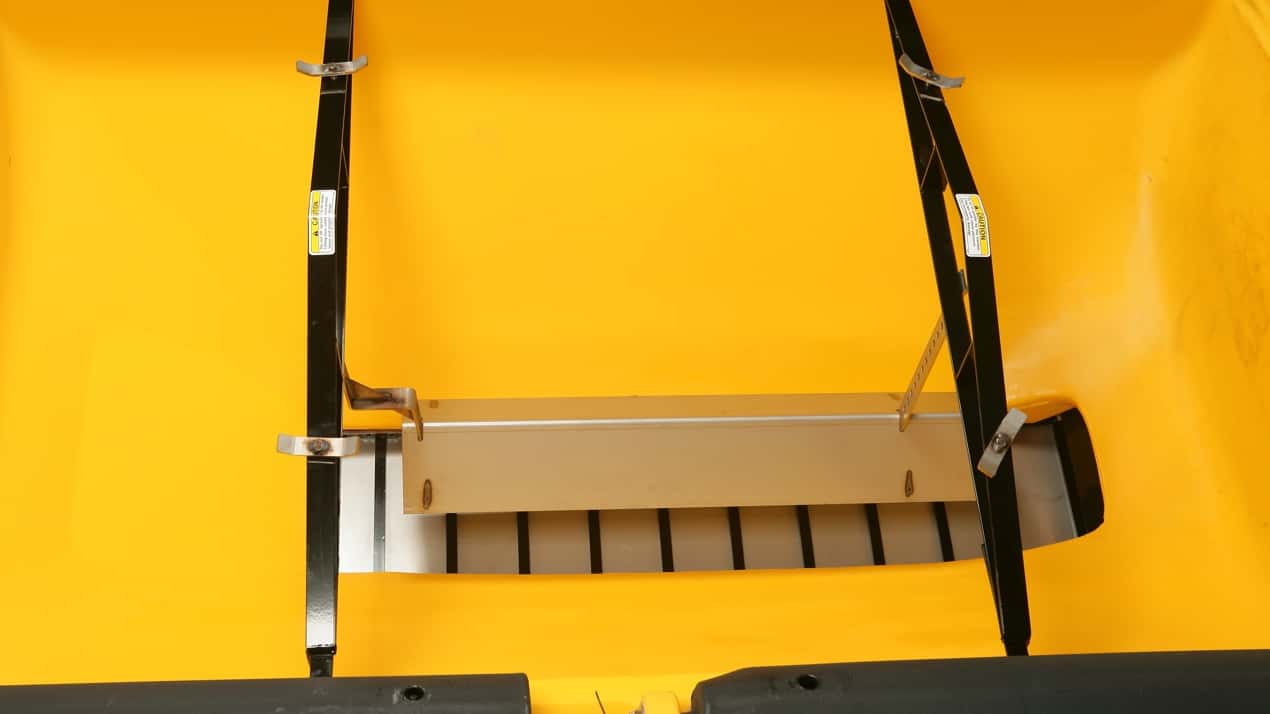

Material Delivery |

Spinner |

|||

| One of the widest in the industry, the 15 ½" pintle chain conveyor moves more material consistently and smoothly to help reduce bridging. Corrosion-resistant stainless steel guides provides extra protection and durability. | An extra large 15 ½" polyurethane spinner delivers a spread pattern of up to 40' and provides long-lasting, corrosion-free operation. | |||

|

|

|||

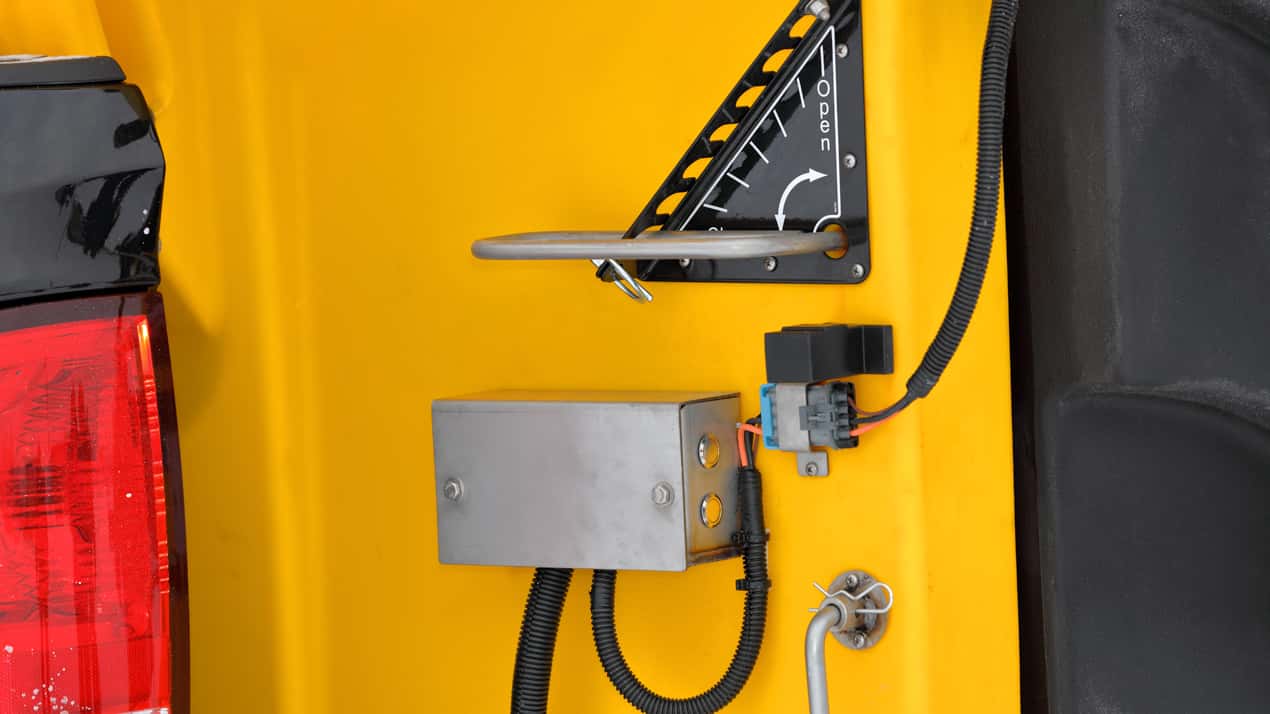

Accessory Integration |

Dump & Work Light Switches |

|||

| Conveniently connect accessories directly into the hub mounted in the back of the hopper. Accessories automatically integrate with the hopper control without having to run additional wires from the front of the truck. | Operators can safely offload material or fill walk-behind spreaders by using the rear-mounted conveyor dump switches. An additional switch is provided so an accessory work light may be conveniently controlled from not only the cab, but also the rear of the hopper. | |||

|

|

|||

Chute Assembly |

Adjustable Feed Gate |

|||

| For precise material application, the adjustable-height chute assembly can be configured for either pickup truck or flat bed and dump body applications, ensuring you're always spreading at the optimum height.

For convenient access to the hitch or material off load, the chute assembly can be removed - no tools required. |

An adjustable feed gate provides additional control of material flow, regardless of material type, reducing waste when traveling between sites. | |||

|

|

|||

Inverted V / Vibrator |

Top Screen |

|||

| An inverted V is available as an accessory to help keep sufficient material weight off of the conveyor, ensuring smooth startup and flow of material.

A vibrator kit is also available as an accessory to help reduce bridging and keep material moving smoothly to the conveyor. |

A steel top screen comes standard, which helps break up large chunks of de-icing material during the loading process to prevent clogging and bridging during spreader operation. | |||

|

|

|||

Ratchet Straps |

Convenient Storage |

|||

| Ratchet straps are available as an accessory for additional spreader stability. | The POLY-CASTER™ hopper spreader slides easily in and out of the vehicle. The entire unit stands on end to minimize the space needed for storage. | |||

|

|

|||

Additional Standard Features |

FLEET FLEX |

|||

| Molded handles and built-in tie-down loops are included for strapping the hopper to the truck. For additional safety, bolting bars are also provided to attach the hopper to the vehicle and a Center High-Mounted Stop Light (CHMSL) is standard. | The POLY-CASTER™ hopper spreader is designed with FLEET FLEX technology for easy interchangeability between electric hopper spreaders without having to change the wiring or the controls.

It provides easy operation, increased reliability, simple wiring and easy installation. Additionally, accessories automatically integrate into the control for easy plug and play. |

|||

PRODUCT SPECIFICATIONS

If you have questions about which FISHER® Poly-Caster™ Spreader is best for you, please call or contact us and we will be happy to assist you. |

DOWNLOAD Spreader Full-line Product Brochure |

|

|||

| FISHER® POLY-CASTER™ Poly Hopper Spreader | ||||||||||||

| Models | 1.5 cu yd | 1.8 cu yd | 2.5 cu yd | |||||||||

| Body Side Length | 7' | 8' | 8' | |||||||||

| Capacity | 1.5 cu yd | 1.8 cu yd | 2.5 cu yd | |||||||||

| Hopper Construction | Polyethylene | Polyethylene | Polyethylene | |||||||||

| Hopper Dimensions (LxWxH) | 96" x 45" x 44" | 104" x 45" x 44" | 104" x 45" x 51" | |||||||||

| Overall Dimensions (LxWxH) | 107 ½" x 63" x 53" | 115 ½" x 63" x 53" | 115 ½" x 63" x 60" | |||||||||

| Min. Bed Length Required | 76" | 84" | 84" | |||||||||

| Approx. Weight (Empty) | 591 lb | 660 lb | 734 lb | |||||||||

| Motor | Dual Electric, 12V, Sealed | Dual Electric, 12V, Sealed | Dual Electric, 12V, Sealed | |||||||||

| Conveyor Width | 15 ½" | 15 ½" | 15 ½" | |||||||||

| Spinner Size | 15 ½" | 15 ½" | 15 ½" | |||||||||

| Spreading Width | Up to 40' ft | Up to 40' ft | Up to 40' ft | |||||||||

| Material | Salt, Sand, Salt/Sand Mix | Salt, Sand, Salt/Sand Mix | Salt, Sand, Salt/Sand Mix | |||||||||

| Vehicle Application | 3/4- & 1-Ton Pickup Trucks | 3/4- & 1-Ton Pickup Trucks | Dump Body or Flatbed Trucks (Over 15,000 lb GVWR) | |||||||||

FISHER® POLY-CASTER™ SPREADER GALLERY